1. With automatic loading and unloading platform, it can effectively improve the production efficiency of cabinets and panelfurniture.

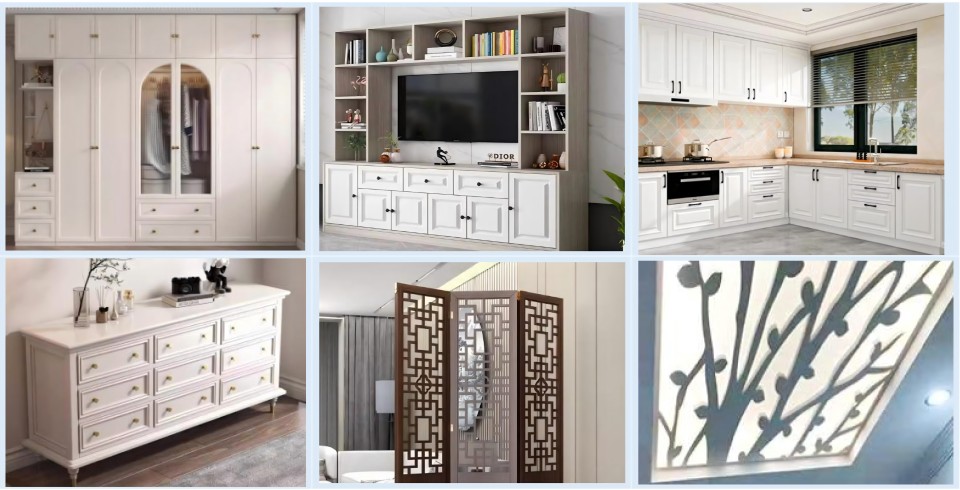

Applications:

1. Woodworking industry

Doors; Cabinets; Tables; Chairs. Wave plate, fine pattern, antique furniture, wooden door, screen, craft sash, composite gates,

cupboard doors, interior doors, sofa legs, headboards and so on.

2. Advertising industry

Signage; Logo; Badges; Display board; Meeting sign board; Billboard Advertising filed, sign making, acrylic engraving and cutting,

crystal word making, blaster molding, and other advertising materials derivatives making.

3. Die industry

A sculpture of copper, aluminum, iron and other metal molds, as well as artificial marble, sand , plastic sheeting, PVC pipe,

and other non-metallic mold.

4. Artwork and Decoration wood crafts; gift box; jewelry box 5. Others Relief sculpture and 3D engraving and Cylindrical object.

Features:

1) Automatic Loading & Unloading machine, be equipped with ATC, L9 drilling bits, Be widely applied for processing closet, cabinet and so on.

2) Appearance: New design gantry cover, whole machine body cover.

3) Pre-position Setting: three vacuum cups to adjust the panel before loading.

4) Back & Side Pusher: Adjust the panel to the right position before processing it

5) Vacuum Detector: Automatically detect if the vacuum power is OK before processing

6) Vacuum Release: Release the vacuum and detect if there is still vacuum working on the panel, if not, then the automatic pusher can push the panel off the vacuum table.

7) Conveyor: Connect to the PLC system, can detect if there is another panel on the waiting table, if not ,then can push the panel to waiting table.

8) Vacuum table: Double PVC layer, 5 vacuum zones for different panel size.

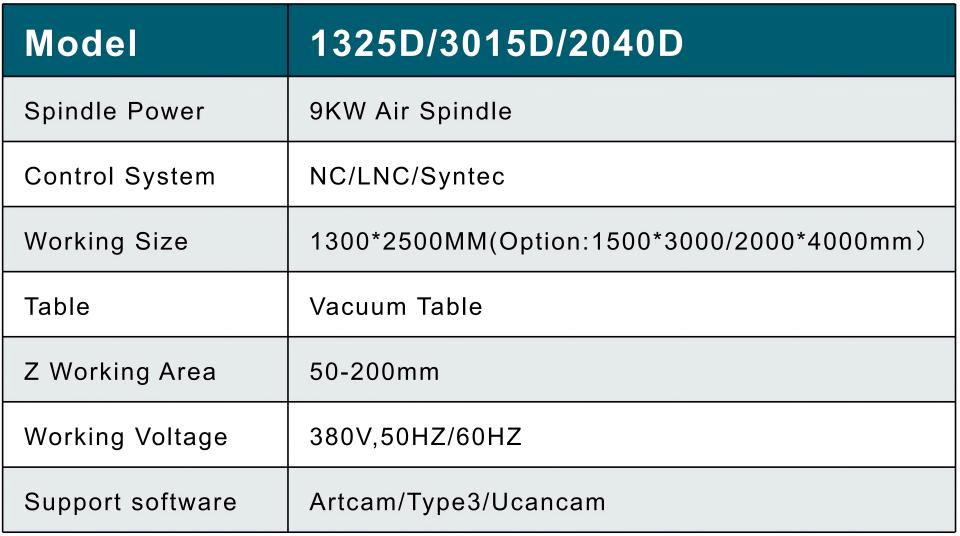

Parameter:

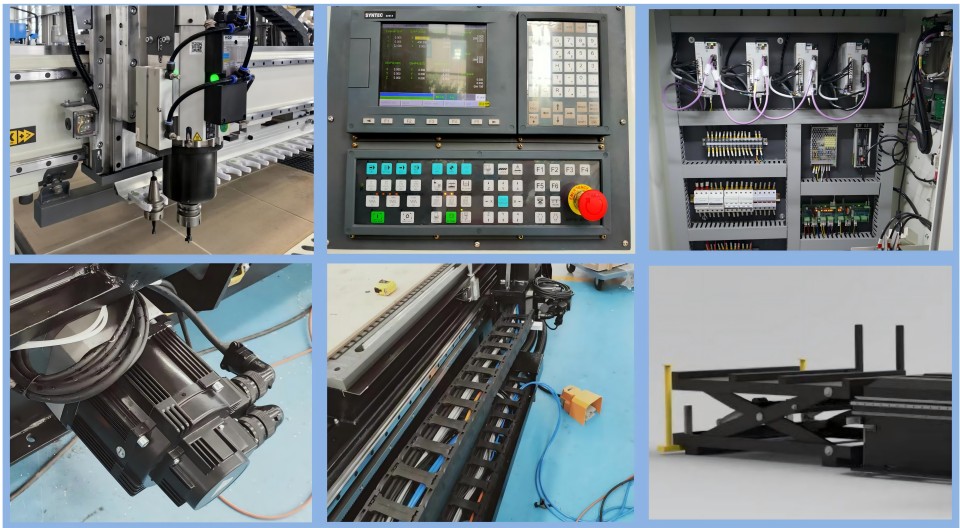

Factory&Machine Show:

Our Service:

Our Service:

Pre-Sales Service

1.We have many exhibitions very year, hundreds of clients was coming to our booth for further communication.

2. 24-hours online Inquiry and consulting support.

3.Support sample testing .

4.We welcome you to visit our factory.

After-Sales Service

1. Training how to instal the machine, training how to use the machine online.

2. Engineers available to clients' factory for training.

3.Guarantee for one year.

4.24-hour technical support by email or calling

5.User-friendly English manual for machine using and maintaining

6.Free technician training for customers.

We know for enterprises, quality is the life, so we have put the quality control into each link as products development, design, purchasing, processing, assembling and testing etc. Everybody in the company are participated into the quality management to prevent any unqualified products from being sent out.

Before delivery, each machine has been inspected through following steps:

1.100% quality testing, that is, each machine has been tested strictly in mechanical assembling and electrical performing \before delivery;

2.100% sample testing, that is, each machine has been tested by the processed sample before delivery;

We always pursue the service philosophy of "ALL FOR CUSTOMERS". The Advanced management system and perfect service system ensure that we can provide timely and efficient services and ensure product's stability in great extent, which supply a effective guarantee for the system normal operation.

Samples Show: