1. Equipped with a fully automatic loading system to reduce dependence on labor and reduce the labor intensity of operators.

2.The auxiliary support system adopts the servo follow-up support, which has higher processing precision in pipe cutting compared

with the variable diameter wheel.

3 Intimate design for front receving table. The cut waste material is automatically dropped to the waste trolley, realizing continuous

processing of pipes; greatly shortening the processing time of new products and reducing development costs.

Introduction:

1.Lasertube systems is 2D and 3D laser cutting systems for tubes, bars and profiles

2.Diameter from 15 mm to 350 mm and length up to 12000 mm in possible

3. High-performance laser device associated with stable operation system enables optimal cutting effects.

4. Perfect cooling, lubrication and dedusting systems ensure stable, efficient and durable performance of the whole machine.

5.Automatic height-adjustment performance keeps constant focal length and stable cutting quality.

6.It could cut mental in various materials and realize excellent and stable cutting effects.

7. Automatic feeding system can realize automatic conveying, cutting, loading and unloading.

Technical Parameter:

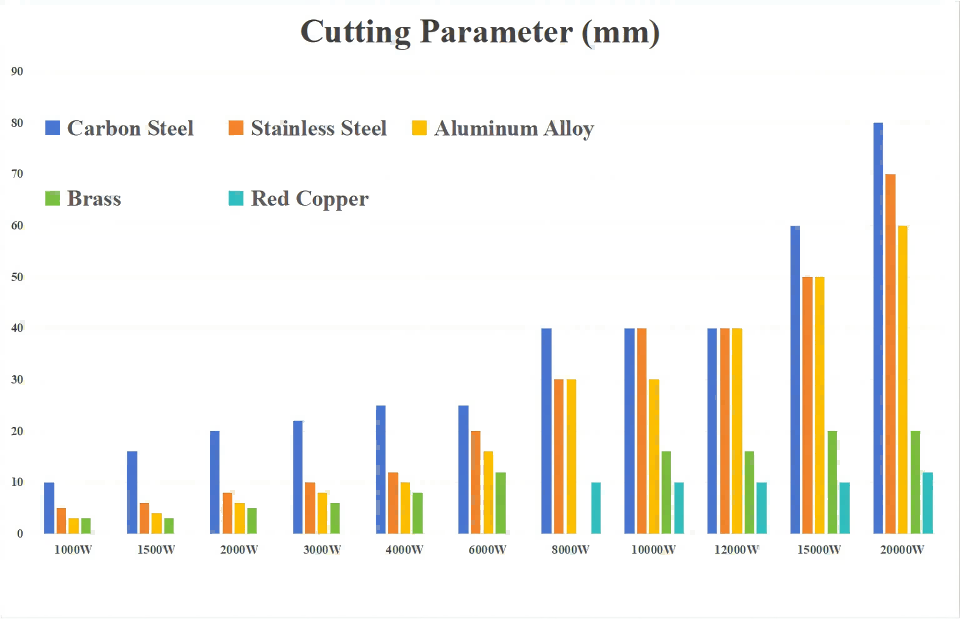

Cutting Parameter:

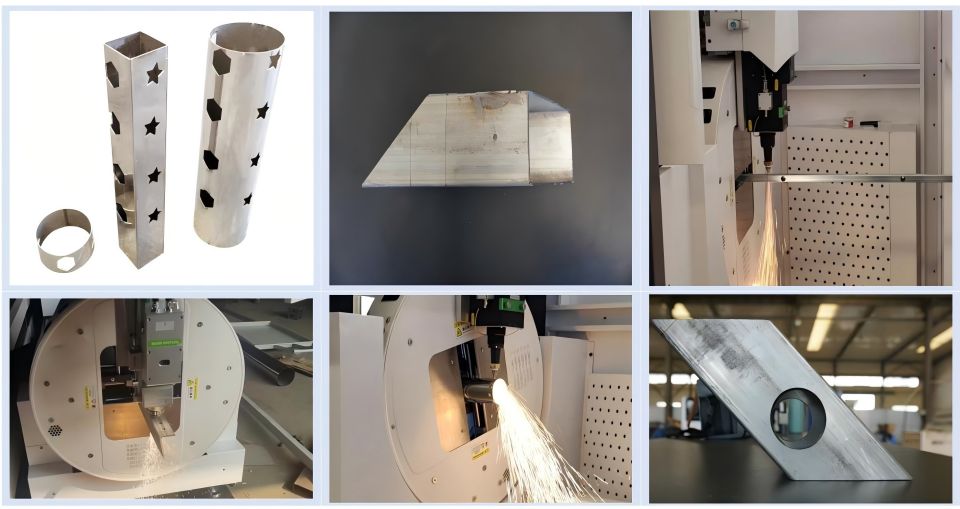

Cutting Samples:

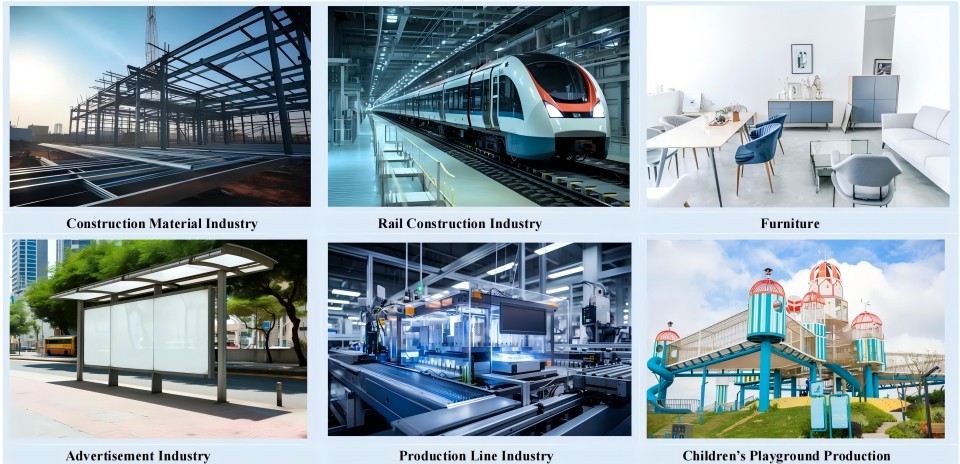

Application: